מעקה הרמה למעלית

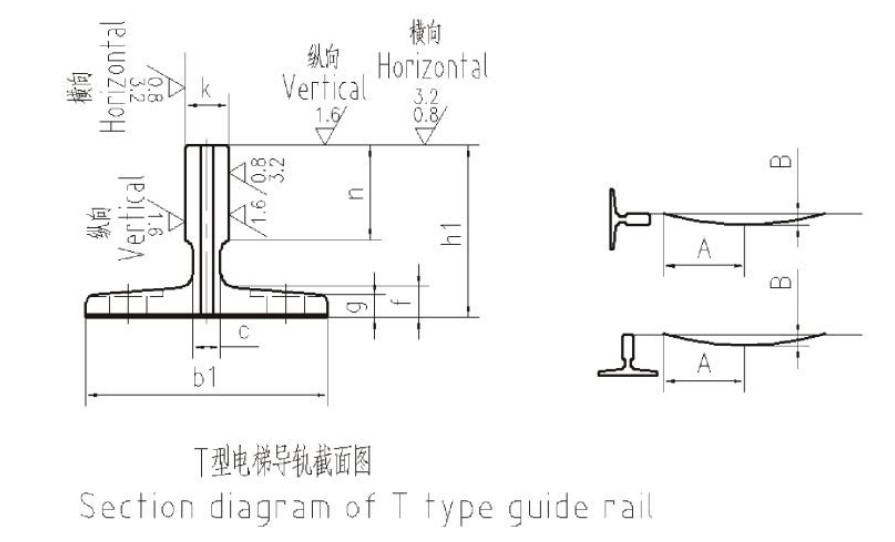

| דֶגֶם | b1 | h1 | k | n | f | g | c |

| T70/B | 70 | 65 | 9 | 34 | 8 | 6 | 6 |

| T75/B | 75 | 62 | 10 | 30 | 9 | 7 | 8 |

| T78/B | 78 | 56 | 10 | 26 | 8.5 | 6 | 7 |

| T82/B | 82.5 | 68.25 | 9 | 25.4 | 8.25 | 6 | 7.5 |

| T89-1 | 89 | 62 | 16 | 32 | 9 | 7 | 8 |

| T89/B | 89 | 62 | 16 | 34 | 11.1 | 7.9 | 10 |

| T90/B | 90 | 75 | 16 | 42 | 10 | 8 | 10 |

| T114/B | 114 | 89 | 16 | 38 | 11 | 8 | 9.5 |

| T127-1/B | 127 | 89 | 16 | 45 | 11 | 8 | 10 |

| T127-2/B | 127 | 89 | 16 | 51 | 15.9 | 12.7 | 10 |

| T140-1/B | 140 | 108 | 19 | 51 | 15.9 | 12.7 | 12.7 |

| T140-2/B | 140 | 102 | 28.6 | 51 | 17.5 | 14.5 | 17.5 |

| T140-3/B | 140 | 127 | 31.75 | 57 | 25.4 | 17.5 | 19 |

| דֶגֶם | b1 | c | f | h1 | h2 | k | n |

| TK3 | 87±1 | ≥1.8 | 2 | 60 |

| 16.4 | 25 |

| TK5 | 3 | ||||||

| TK3A | 78±1 | ≥1.8 | 2.2 | 60 | 10±1 | 16.4 | 25 |

| TK5A | 3.2 |

1. מסילת מדריך מעלית מעובדת

2. מעקה מדריך מעלית נמשכת קרה

3. רכבת מדריך מעלית מותאמת אישית

4. מעקה מדריך חלול למעלית

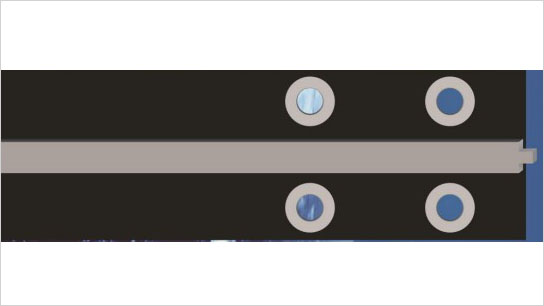

5. לוחות דיג למסילות מובילות מעלית בציפוי קר, לוחות דיג למסילות מובילות מעלית מעובדות, לוחות דיג בעובי מיוחד, לוחות דיג בחתך T, קליפסים מזויפים, מלחציים הזזה, קליפסים הזזה, קליפסים T.

6. תקן: ISO 7465.

7. דגם: T45A, T50A, T70B, T75B, T78B, T82B, T89B, T90B, T114B, T127B, TK3, TK3A, TK5, TK5A.

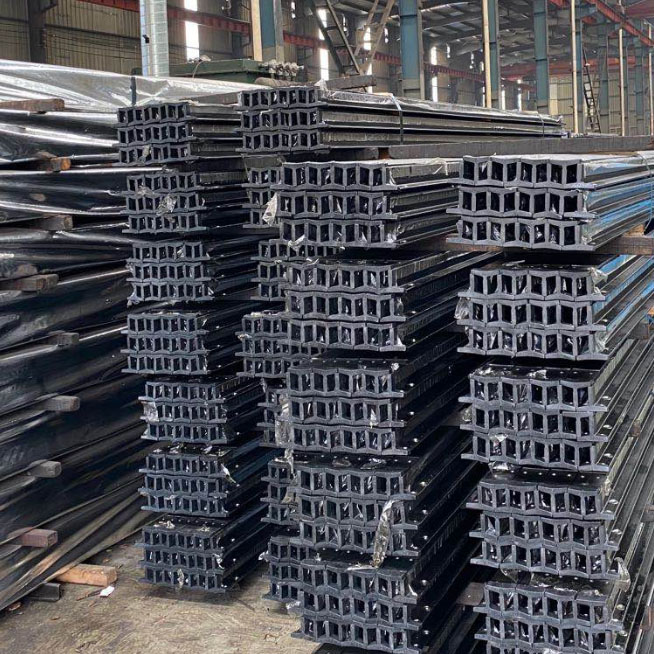

8. אריזה: מסילות ההדרכה שלנו ארוזות בחבילות, עם כיסויי מגן בשני הקצוות, וכל חבילה ארוזה ביריעת פלסטיק. אנו יכולים גם לארוז בהתאם לדרישות שלכם.

9. אנו יכולים לספק מסילות מדריך של מותגים כמו MARAZZI וכו'.

מסילת ההדרכה של המעלית היא מסילה בטוחה עבור המעלית לעלות ולרדת בתא המעלית, ומבטיחה שהקרון והמשקל הנגדי יעלו ולמטה לאורכה. מסילת ההדרכה מחברת את הפלטה ואת תושבת מסילת ההדרכה לקיר תא המעלית כדי לספק הנחיה לקרון המעלית ולמשקל הנגדי. תפקיד התמיכה של קליפר הבטיחות בעת בלימה הוא חלק חשוב במערכת המעלית. מסילת ההדרכה הנפוצה במעליות היא מסילת הדרכה בצורת "T". מאפיינים כגון קשיחות חזקה, אמינות גבוהה, בטיחות ועלות נמוכה. מישור מסילת ההדרכה חייב להיות חלק, ללא משטח לא אחיד גלוי. מכיוון שמסילת ההדרכה היא מסילת ההסעה של נעלי ההדרכה וציוד הבטיחות בקרון המעלית, יש להבטיח מרווח במהלך ההתקנה. יחד עם זאת, מסילת ההדרכה צריכה לשאת באחריות לעצור את המעלית במקרה של תאונת מהירות יתר, כך שלא ניתן להתעלם מקשיחותה.

מסילות הנחיה של מעליות מחולקות ל: מסילות הנחיה מוצקות ומסילות הנחיה חלולות עם משקל נגד.

מסילת הנחיה מוצקה היא מסילת הנחיה מעובדת, אשר נוצרת על ידי עיבוד שבבי של משטח ההנחיה וחיבור חלקים של פרופיל מסילת ההנחיה. מטרתה לספק הנחיה להפעלת תא המעלית במהלך הפעלת המעלית. מסילת ההנחיה הקטנה והמוצקה משמשת גם להנחיית משקל נגד. ישנם מפרטים רבים של מסילות הנחיה מוצקות בהתאם לרוחב רצפת מסילת ההנחיה, אשר ניתן לחלק ל-T45, T50, T70, T75, T78, T82, T89, T90, T114, T127, T140 וכו'.

מסילות הנחיה חלולות של משקל נגד הן מסילות הנחיה מתגלגלות בעיצוב קר בעוביים של 2.75 מ"מ ו-3.0 מ"מ. הן מעוצבות בקור מפלטות מפותלות דרך תבניות מרובות מעברים. הן משמשות בעיקר כדי לספק הנחיה למשקל הנגד במהלך פעולת המעלית. ניתן לחלק מסילות הנחיה חלולות לצדדים ישרים ולצדדים אוגנים בהתאם לצורת משטח הקצה של מסילת ההנחיה, כלומר TK5 ו-TK5A.